Elettrogas Aravon

In-house production since 1961. Reliability that lasts.

Direct manufacturer contact:

Elettrogas Aravon di Bettetini Nicola

Via Italia 1 - Caltignaga (NO) - Italy

tel/WA +39 349 83 93 208

office: info@aravon.it

Technical and distributor enquiries welcome

web copyright: 1998 by Elettrogas Aravon

Italian Original Manufaturer of Engineed Components

Click in half to download PDF catalogue

All products included are of original design and internal production at Aravon

Some patents are still valid, others recall our history

|

Elettrogas Aravon, or simply Aravon, is a 100% Italian manufacturer of engineered components for yacths and boats, for RV and industrial application.

|

Company profile

Aravon designs and produces original with standard measures and customizable components to international OEMs, distributors and industrial partners.All core activities are carried out in-house, including: functional study and physical calculations, overall design, stylistic revision, technical drawing for single components and tools needs, revision for cad-cam, create molds for both metal and plastic, production with with lathes, casting or injection, CNC modifications, polishing and galvanic finishing, assembly, quality control and functional testing. Aravon operates as a long-term supplier for european and international oems and industrial equipment manufacturers. |  |

Manufacturing Capabilities

|

|

Markets Serced

Aravon supplies OEMs, distributors and industrial partners in multiple international markets.

The company supports international customers with stable production, consistent lead times and long-term supply continuity. |  |

TRUST & MEMBERSHIPS

|

Each of our products borned from direct experience, through comparisons with users, created from our original designs and molds. 60 years of experience on the sea and on the road are a great help to those who venture out today.

|

Our story

The Bettetini family has distant Swiss origins, having first emigrated to Milan and then settled over 100 years ago on the island of San Giulio on Lake Orta.

- In 2025 we reintroduced finishes such as bronze and all-black and some customers asked us for fine wood components to complement our line. - We haven't forgotten the environment: while solar panels reduce our need for external energy sources, managing our family forests and producing corn allows us to offset residual CO2 emissions. Today, we can truly say that each of our products protects the health of planet Earth because their production does not cause an increase in CO2. |  |

Enhanced Product Documentation for Durability & Repair

Detailed visual guides for installation, components, and maintenance.

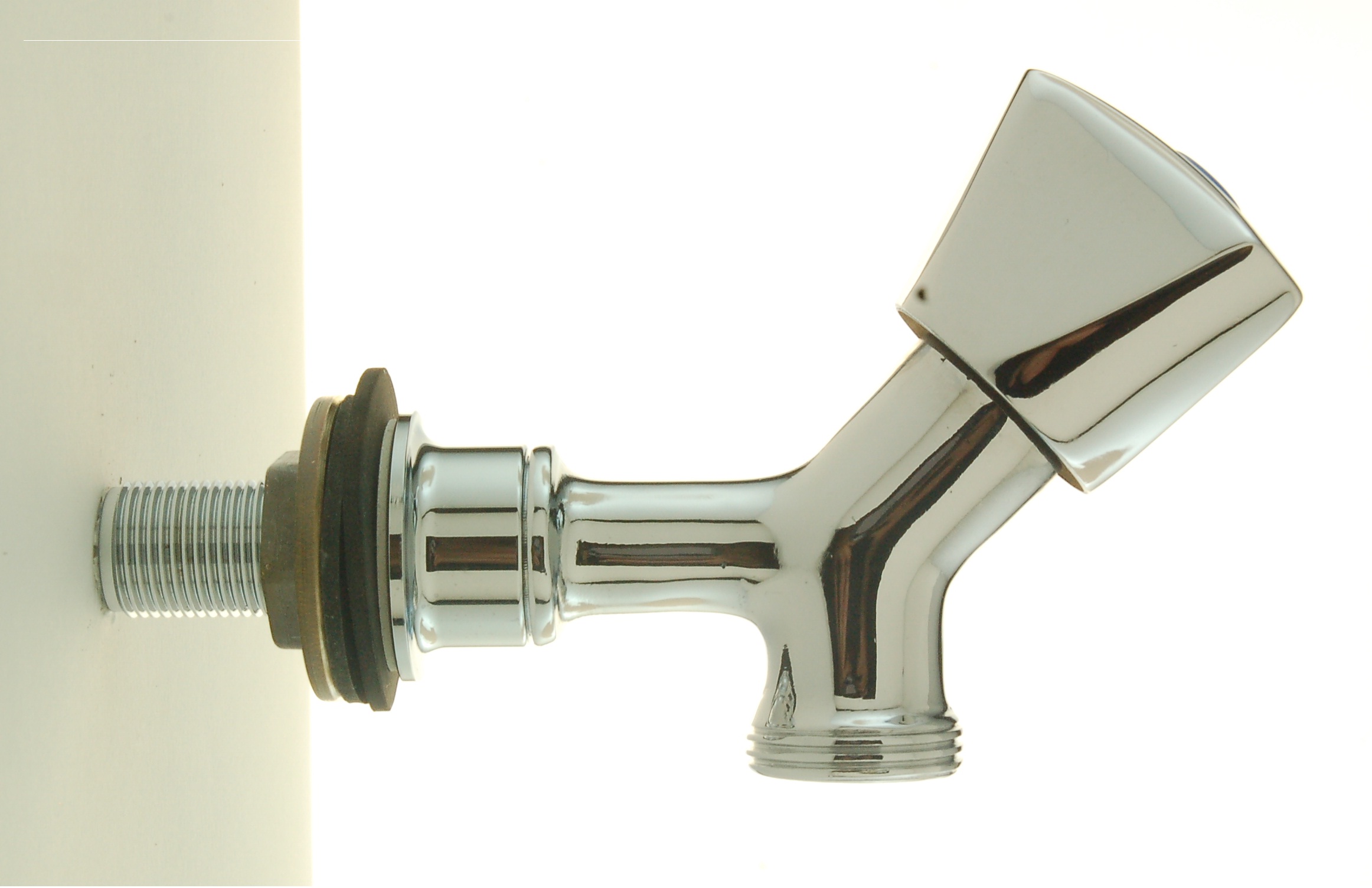

02Single taps for fast washer with only cold water.

12Washer machine tap

|